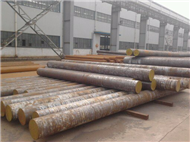

42 crmo4 round steel components/forging round steel price/gear shaft forgings

Product class:Forging round steel

Release date:2025-7-7 10:11:45

The forged materials produced by our company have undergone three chemical composition tests and two forgings, which have ensured the quality and mechanical properties of the products. Each product has undergone UT instrument flaw detection, strictly eliminating the problems of white spots, cracks and slag addition, and can be produced according to the requirements of customers, thus better ensuring the variability of processed products and reducing the waste of raw materials. The products have passed ISO 9001: 2000 quality management system certification, CCS of China, RINA of Italy, KR of Korea, NK of Japan Maritime Association, BV of France, ABS of the United States, RS of Russia, Lloyd''s LR of Britain, GL Classification Society of Germany, and quality system certification of military weapons and equipment.

Product specifications: forging material φ 80-φ 1200 mm, square billet 80-1200 mm.

Length: 3-16m, or according to customer''s requirements, provide fixed-length delivery.

Forging ratio: ≥4:1, straightness: ≤3mm/1000mm

Grain size: ≥ grade 6 h: ≤ 2.0ppm

Non-metallic inclusion: coarse value ≤2.0 fine value ≤2.0

Diameter Tolerance: -0/+3mm Surface Delivery Status: Black Skin/Polishing/Turning

Flaw detection standard: according to GB/T 6402, level I/ii/iii is guaranteed. According to export standards: SEP1921 CLASS C/C, D/D, e/e.

Reference standard number: DIN 7527-6/EN 10204/SEP1921/EN 10228-3/EN 10250/EN 10083/SEW 550

Steelmaking process: EAF electric arc furnace +LF refining +VD vacuum degassing furnace (feeding Ca-Si wire)+steel ingot (bottom pouring/argon gas protection)+forging+annealing+black skin polishing (turning)+SEP1921 C/c grade flaw detection+sawing at both ends

Heat treatment: normalizing/annealing+quenching/tempering. We can also provide the required delivery status according to customer requirements.

Product specifications: forging material φ 80-φ 1200 mm, square billet 80-1200 mm.

Length: 3-16m, or according to customer''s requirements, provide fixed-length delivery.

Forging ratio: ≥4:1, straightness: ≤3mm/1000mm

Grain size: ≥ grade 6 h: ≤ 2.0ppm

Non-metallic inclusion: coarse value ≤2.0 fine value ≤2.0

Diameter Tolerance: -0/+3mm Surface Delivery Status: Black Skin/Polishing/Turning

Flaw detection standard: according to GB/T 6402, level I/ii/iii is guaranteed. According to export standards: SEP1921 CLASS C/C, D/D, e/e.

Reference standard number: DIN 7527-6/EN 10204/SEP1921/EN 10228-3/EN 10250/EN 10083/SEW 550

Steelmaking process: EAF electric arc furnace +LF refining +VD vacuum degassing furnace (feeding Ca-Si wire)+steel ingot (bottom pouring/argon gas protection)+forging+annealing+black skin polishing (turning)+SEP1921 C/c grade flaw detection+sawing at both ends

Heat treatment: normalizing/annealing+quenching/tempering. We can also provide the required delivery status according to customer requirements.

Market value:¥0.00

Site price:¥0.00

Product order hotline:13345188345

furniture

product category

Classification

Recommended

-

SAE4340/AISI4340 rail locomotives drive shaft gear steel

Market value:¥0.00 Site price:¥0.00 -

18 crnimo7-6 carburized gear steel/locomotive forging shaft price

Market value:¥0.00 Site price:¥0.00 -

17 crnimo6 overloaded motorcycle gear steel/shaft forgings

Market value:¥0.00 Site price:¥0.00 -

36 nicrmo16 nuclear power support material/round steel components/gear shaft forgings

Market value:¥0.00 Site price:¥0.00

information

Qilute Steel specializes i...

Qilute Steel specializes i...Qilute Steel Co., Ltd. specializes in the production of large-caliber thick-wall...

Contact us

Phone: 0537-3125088

Fax: 0537-3120088

Mobile: 13345188345

Email: qltgyxgs@163.com

Website: http://m.xyqm01.cn

Address: 29 Longqiao North Road, Yanzhou, Jining City, Shandong Province

parameters

details

42CrMo4(1.7225) Alloy Structural Steel Implementation standard: EN 10083/1-1991 Characteristics: 42CrMo4 has high strength, hardenability, good toughness, small deformation during quenching, and high creep strength and durable strength at high temperature. Chemical composition Carbon C: 0.38-0.45 Silicon Si: ≤ 0.40 Mn: 0.60-0.90 Sulfur S: Allowable Residual Content ≤0.035 Phosphorus p: allowable residual content ≤0.035 Cr: 0.90-1.20 Mo: 0.15-0.30 ● 42crmo 4 standard control: China GB 42CrMo, Russia ГOCT 38XM, us AISI 4140/4142, UK BS 708M40/708A42/709M40, France NF 40CD4/42CD4, Germany DIN 41CrMo4/42CrMo4, Japan JIS SCM4, international ISO 683/1 3 Mechanical properties Tensile strength σ b (MPa): ≥ 1080 (110) Yield strength σ s (MPa): ≥ 930 (95) Elongation Δ 5 (%): ≥ 12 Section shrinkage Ψ (%): ≥ 45 Akv (j) of impact power: ≥ 63 Impact toughness value αkv (J/cm² ):≥78(8) Hardness: ≤217HB Sample size: the sample blank size is 25 mm. Sales hotline: 13345188345, service hotline: 0537-3125088